The controller design and tuning recipe we have used so successfully on this site requires that we bump our process and collect dynamic data as the process responds.

For the heat exchanger and gravity drained tanks study, we generated dynamic data using a step test while the controller was in manual mode. One benefit of this “open loop” step test is that we can analyze the response graph by hand to compute first order plus dead time (FOPDT) dynamic model parameters. These parameter values are then used in rules and correlations to complete the controller design and tuning.

In a production environment, operations personnel may not be willing to open a loop and switch to manual mode “just” so we can perform a bump test on a process. In these situations, we must be prepared to perform our dynamic testing when the controller is in automatic.

Arguably, such closed-loop testing offers potential benefits. Presumably, operation is safer while under automatic control. And closed loop testing should enable us to generate dynamic data and return to steady operation faster than other bump test method.

Software Required

Unfortunately, once we deviate from the pure manual mode step test, we must use a software tool to fit an FOPDT model to the data. Fortunately, inexpensive software is available that helps us perform our data analysis and controller tuning chores quickly and reliably.

In theory, closed loop dynamic testing can be problematic because the information contained in the process data will reflect both the character of the controller as well as that of the process. If we remain conscious of this and take modest precautions, this theoretical concern rarely causes real world problems.

Generating Dynamic Data in Automatic Mode

For closed loop studies, dynamic test data is generated by stepping, pulsing or otherwise bumping the set point.

For model fitting purposes, the controller, when working to track this set point bump, must take actions that are energetic enough to generate a proper data set, but not be so aggressive that the PV oscillates wildly during data collection.

Similar to manual mode testing, a proper data set is generated when the controller output (CO) is moved far enough and fast enough to force a clear response in the measured process variable (PV).

Also, similar to manual mode testing, the process must be at a steady operation before first bumping the set point. The point of a bump test is to learn about the cause-and-effect relationship between the CO and PV. With the plant at a steady operation, we are starting with a clean slate and the dynamic character of the process will be clearly revealed as the PV responds. Just be sure to have the data capture routine collect the entire event, starting from before the initial bump.

Set Point Bumps to the Heat Exchanger

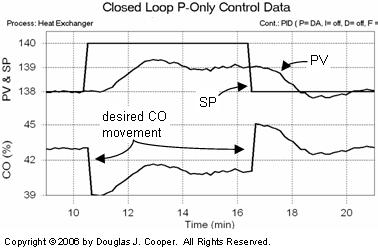

Below is the heat exchanger process under P-Only control. As shown (click for a large view), the process is initially at a steady operation. The set point is stepped from 138 °C up to 140 °C and back again. The P-Only controller produces a moderate set point response, with offset displayed as expected from this simple controller form.

What is important in the above test is that when the set point is stepped, the P-Only controller is active enough to move the CO in the desired “far enough and fast enough” manner to force a clear response in the PV trace. This obvious CO to PV cause-and-effect relationship is exactly what we require in a good data set.

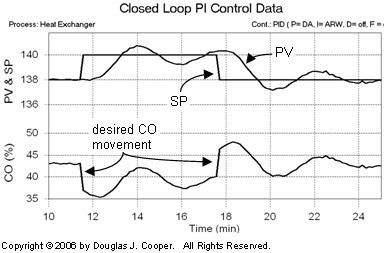

Below is the heat exchanger process with a poorly tuned PI controller. Again, the process is initially at a steady operation and the set point is stepped from 138 °C up to 140 °C and back (click for a large view).

This process is approaching the upper extreme of energetic oscillations. But as noted on the plot, we can still see the desired clear and sudden CO movement that forces the PV dynamics needed for a good FOPDT model fit.

Automated Model Fitting

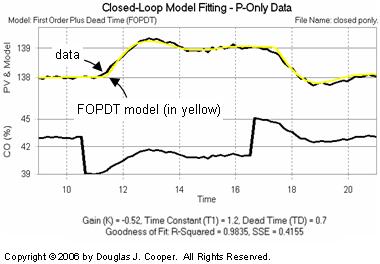

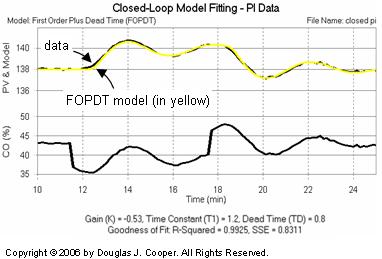

Below we fit a FOPDT model to the process data from the above two set point bump tests. We use the Control Station Engineer software in these examples.

Here is an automated model fit of the above P-Only control data (click for a large view) using the Control Station software:

And here is an automated model fit of the above PI control data (click for a large view) using the software:

Comparing Results

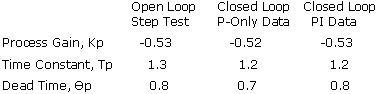

The table below compares the FOPDT model parameters from the above set point driven bump test against the open loop step test results presented in a previous article:

The table confirms what we can see visually in the model fit plots; it is certainly possible to obtain an accurate FOPDT dynamic model from closed loop data.

Implications for Control

The small differences in parameter values in the above table will have negligible impact on controller design and tuning. In fact, real world process data is imperfect and differences should be expected, even when repeating the identical test on the same process.

The use of these model parameters for controller design and tuning of the heat exchanger can be found at these links for P-Only, PI, PID and PID with Filter control.