The design and tuning of a three mode PID controller follows the proven recipe we have used with success for P-Only control (e.g., here and here) and PI Control (e.g., here,here and here). The decisions and procedures we established for steps 1-3 of the design and tuning recipe in these previous studies remain unchanged as we move on to the PID algorithm.

Step 4 of the recipe remains the same as well. But it is essential in this step that we match the rules and correlations of step 4 with the particular controller algorithm form we are using.

The challenge arises because the number of PID algorithm forms available from hardware vendors increases markedly when derivative action is included. And unfortunately, these PID algorithms are implemented in many different forms across the commercial market.

The potential for confusion by even a careful practitioner is significant. For example:

▪ there are three popular PID algorithm forms, and

▪ each of these three forms have multiple parameters that are cast in different ways.

As a result, there are literally dozens of possible PID algorithm forms. Matching each controller form with its proper design rules and correlations requires careful attention if performed without the help of software tools.

Common Algorithm Forms

Listed below are the three common PID controller forms. If offered as an option by our vendor (most do offer it), derivative on measured process variable (PV) is the recommended PID form:

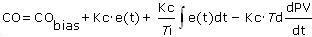

· Dependent, ideal PID controller form (derivative on measurement):

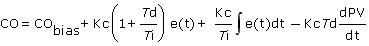

· Dependent, interacting form (derivative on measurement):

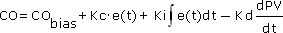

· Independent PID form (derivative on measurement):

Where for the above:

CO = controller output signal (the wire out)

CObias = controller bias; set by bumpless transfer

e(t) = current controller error, defined as SP – PV

SP = set point

PV = measured process variable (the wire in)

Kc = controller gain (also called proportional gain), a tuning parameter

Ki = integral gain, a tuning parameter

Kd = derivative gain, a tuning parameter

Ti = reset time, a tuning parameter

Td = derivative time, a tuning parameter

Tuning parameters

Because there has been little standardization on nomenclature, the same tuning parameters can appear under different names in the commercial market. Perhaps more unfortunate, the same parameter can even have a different name within a single company’s product line.

We will not attempt to list all of the different names here, though we will look at a solution to this issue later in this article. A few notes to consider:

| 1) | The dependent forms appear most in products commonly used in the process industries, but the independent form is not uncommon. |

| 2) | The majority of DCS and PLC systems now use controller gain, Kc, for their dependent PID algorithms. There are notable exceptions, however, such as Foxboro who uses proportional band (PB = 100/Kc assuming PV and CO both range from 0 to 100%). |

| 3) | Reset time, Ti, is slightly more common for the dependent PID algorithms, though it is rarely called that in product documentation. Reset rate, defined as Tr = 1/Ti, comes in a close second. Again, the name for this parameter changes with product. |

| 4) | Most vendors use derivative time, Td, for their dependent PID algorithms, though few refer to it by that name in their product documentation. |

Tune One, Tune Them All

Some good news in all this confusion is that the different forms, if tuned with the proper correlations, will perform exactly the same. No one form is better than another, it is just expressed differently.

In fact, we can show equivalence among the parameters, and thus algorithms, with these relations.

Though not presented here, analogous conversion relations can be developed for forms expressed using proportional band and/or reset rate.

Clarity in the Chaos

It is perhaps reasonable to hope that industrial practitioners will have an intuitive understanding of proportional, integral and derivative action. They might know the benefits each term offers and problems each presents. And experienced practitioners will know how design, tune and validate a PID implementation.

Expecting a practitioner to convert that knowledge and intuition over into the confusion of the commercial PID marketplace might not be so reasonable.

Given this, the best solution for those in the real world is to use software that lets us focus on the big picture while the software ensures that details are properly addressed.

Such productivity software should not only provide a “click and go” approach to algorithm and tuning parameter selection, but should also provide this information simply based on our choice of equipment manufacturer and product line.

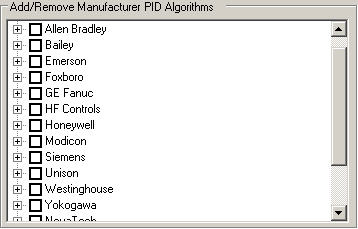

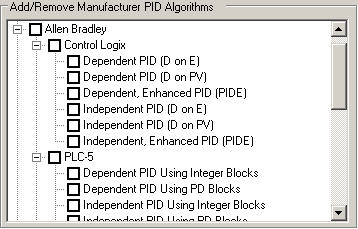

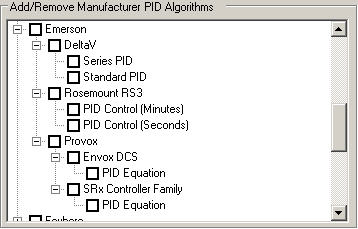

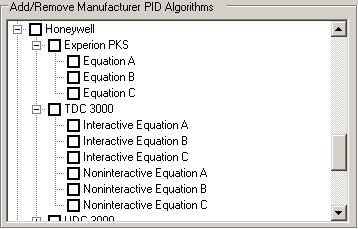

For example, below is a portion of the controller manufacturer selection available in one commercial software package:

If you select Allen Bradley, Emerson, and Honeywell in the above list, the choice of PID controllers for each company is shown in the next three images:

It is clear from these displays that there are different terms and many options for us to select from, all for PID control. And it may not be obvious that the different terms above refer to some version of our “basic three” PID forms.

Too much is at stake in a plant to ask a practitioner to keep track of it all. Software can get us past the details during PID controller design and tuning so we can focus on mission-critical control tasks like improving safety, performance and profitability.

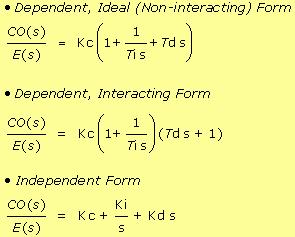

Note: the Laplace domain is a subject that most control practitioners can avoid their entire careers, but it provides is a certain mathematical “elegance.”Below, for example, are the three controller forms assuming derivative on error. Even without familiarity with Laplace, perhaps you will agree the three PID forms indeed look like part of the same family:  |